How Do Infrared Refrigerant Leak Detectors Work?

Governments around the world are issuing new regulations to reduce emissions, save energy, and improve safety. Therefore, many refrigeration systems need to be leak tested to reduce the risk of leakage, Effective refrigerant leak detection is vital for ensuring safety and achieving compliance as well as maximizing energy efficiency and minimizing operation costs.

Infrared refrigerant leak detectors are an essential tool for finding leaks in refrigerant systems and have grown in popularity over recent years. An infrared leak detector draws the sample across an optical sensor that analyzes how much IR radiation the sample has absorbed, allowing technicians to quickly and accurately locate the source of the leak. In this paper, we will discuss how infrared refrigerant leak detectors work and the Pros and Cons they offer.

Infrared Leak Detection Principle

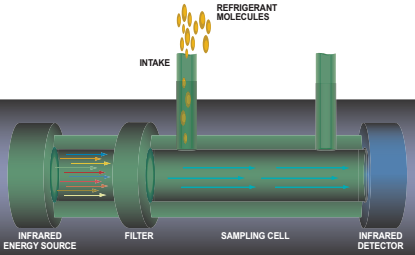

Non-dispersive infrared sensor: (NDIR sensor)

This sensor mainly uses the infrared detection principle. A leak detection method that uses the infrared principle to identify the presence and concentration of the selected gas, Because the infrared light is affected by the sample gas, the infrared light of the corresponding wavelength changes, which is generated at the receiving output end. change results. By controlling the optical filter, the infrared wavelength is controlled in a selected range to ensure the coverage of all selected gases. Through the calculation and analysis of the infrared receiver data, the interference data is filtered out and the leak point is accurately located.

Pros

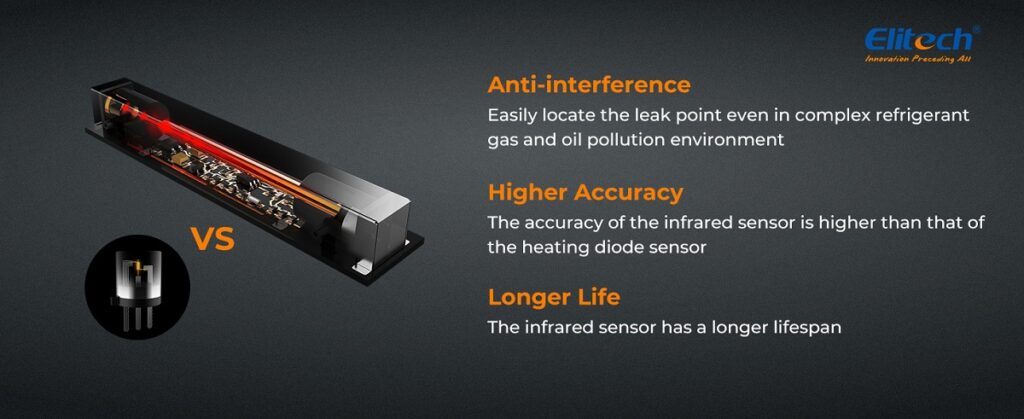

The sensitivity levels on Infrared sniffers are top-notch. Most of these Detectors can detect leaks as low as 0.10 ounces per year. This is as good as it gets as far as sensitivity.

The lifespan of an Infrared sensor is much longer than your typical leak detector. While standard detectors on the market may have their sensors last for twenty, thirty, or fifty hours of work an Infrared detection unit will see its sensor last up to ten years. Imagine that, not having to change the sensor on your detector for ten years. You save yourself the hassle as well as the money.

Compared with the heated diode leak detector, the infrared refrigerant leak detector has strong anti-interference ability, easy to detect leaks in complex environments, and minimizes false alarms caused by common chemicalsT

Cons

Well, folks with top quality come at top prices. These types of units are the best detectors on the market today but the price is quite expensive. Most Infrared units are between three hundred to four-hundred dollars a unit.

The Elitech ILD-200 Infrared leak detectors is a trusted solution.

Independent research and development of infrared sensors, the perfect smart function with the same price level as the heated diode leak detector.

Thank you for reading. Please feel free to contact Elitech for further information about infrared refrigerant leak detectors.